BATTERY MATERIALS

Supporting the battery industry

The consumers demand for more electric solutions have been rapidly increasing, from EVs (electric vehicles) to e-bikes and from power tools to smartphones. Hence, the battery technology industry has been exponentially growing as well. Battery manufacturers have to constantly maintain their competitiveness of world-class battery technology.

The chemical industry is innovating relentlessly to provide the best solutions and improvements in Battery Materials. Techlink and SAFI-Valves are collaborating to provide the best equipment in flow control and anti-corrosive valves to support the Cathode Material industry with all their requirements.

Techlink design and build reactor pilots for battery material based on research executed inhouse on material improvements.

The best solutions and equipment in

flow control and anti-corrosion valves

for the cathode material industry

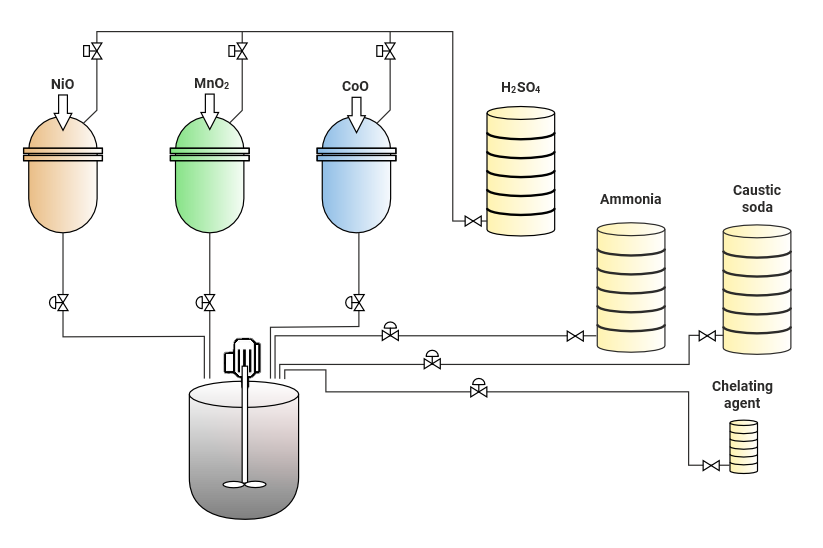

The NCM and NCA processes involve the handling of corrosive and abrasive liquids that must be precisely dosed into reactors. The dosing precision, as well as the purity of the reagents is of paramount importance. Pollution by undesirable metallic ions can lead to disasters.

TECHLINK control valves offer the best resistance to both corrosion and erosion, and a high level of reliability and precision.

Our valves guarantee the absence of unwanted metal in your product, such as Cu, Zn or Fe.

They are perfectly adapted to the processes of NCM and NCA manufacturing.